Three Planes for Cutting Rabbets

Megan Fitzpatrick favors a straight rabbet plane, a shoulder plane, or a skew rabbet/moving fillister for this task.

I have two favorite ways to make backboards: shiplap joints and tongue-and-groove joints*.

For shiplap joints – a series of mating rabbets – there are several handplane options, and students typically already own at least one of the three I favor: a straight rabbet, a shoulder plane, or a skew rabbet/moving fillister (as shown at the top of this post).

Skew rabbet plane

Of the ones shown above, the Veritas skew rabbet plane is by far the fastest. (And because it has a nicker, depth stop, and movable fence, it is technically a moving fillister plane – a plane designed to be used both with and across the grain.) But it can be tricky for beginners to cut a 90° rabbet with this plane; it’s all too easy to tip it off the work a little bit, and end up with a sloped rabbet. I’ve found that the knob on the front exacerbates this tendency; that’s why I confiscate them. (Someday, I’ll make a coat rack out of the many I’ve acquired.)

But with a little practice, it’s quick and easy. Set the depth stop to a hair more than half the thickness of the workpiece, and set the fence to the width of the rabbet you want to cut. (I usually aim for about 3/8 in. or a little more on backboards, depending on the size of the project.) Cinch down tight on both. I use nylon-jawed pliers to tighten the knobs.

Each hand has one job: The right hand pushes (this is for a right-handed plane; the skew rabbet is also available as a left-handed plane, to use in the other direction), and does so without grasping the handle too hard (which can make the plane wobble). The left hand holds the plane firmly at 90° to the work, with fingers pressing the plane’s fence into the work and the thumb pressing down (right where the knob used to be).

Start at the near end of the board and pull back a few inches, then take a short stroke, repeat with a slightly longer stroke, and again, working your way back until you’ve established the full length of the rabbet. A few short strokes to establish the shoulder are easier to get right than one long stroke. Why pull back? It’s mostly habit: When cutting across the grain with this plane, drop the nicker to score the shoulder as you pull back to effect a cleaner cut. (Lie-Nielsen makes a skew rabbeting block plane, the No. 140, which is not a moving fillister plane – no depth stop.)

Work your way down to final depth and width; the fence and depth stop will tell you when you’re done. Then check the rabbet to make sure it’s square, especially if you’re new to this method. (And if you’re not, a few strokes holding the plane at 90° will hopefully solve the problem – plus you’ll know where to concentrate your attention on the next cut.)

Straight rabbet plane

Another fast, and almost always successful method for those new to hand tools, is to use a straight rabbet plane against a fence. The only tricky thing is to keep an eye on the baseline, and stop cutting when you reach it.

Mark the depth and width of the rabbet with a marking gauge, then clamp a long, straight piece of scrap at the marked line on the top. Again, each hand has a specific job – much the same as above (except a straight rabbet can be used with either hand as the dominant hand). The dominant hand pushes, the off hand pushes in and down. Again, work your way back to establish the full length of the rabbet. And again, check your work.

Shoulder plane

I do not like using a shoulder plane to cut rabbets. This plane is designed for precision work, and as such takes only fine cuts. So it takes (comparatively) forever to cut rabbets with it. What it has going for it, however, is its sharp arris, which can assist in making this cut.

Establish the shoulder and depth with a marking gauge, and be sure to cut that shoulder line deep. Carefully now, put the corner of the shoulder plane into that cut line at an angle, then make a cut – still at an angle – all the way down the workpiece. Repeat a few times, each time bringing the plane closer to level. You are establishing a V-cut shoulder.

After the V-cut is deep enough to register the plane against it at 90°, finish the cut at 90°, pressing the plane into the shoulder.

Yes, I could use this method with my straight rabbet plane, too – but it’s a little trickier because the corner of my wooden plane isn’t as sharp as that on my metal shoulder plane.

What about a rabbeting block plane or rabbeting jack plane? Well, I don’t really like planes that are meant to do multiple jobs…and I always cut myself when using a rabbeting block plane as a “regular” block plane. But more important than my clumsiness is that it’s fairly easy to flex the sole of these planes by tightening the lever cap too much. (The same is true on shoulder planes – but you’d have to severely over-tighten to flex the sole on that plane).

*I’ll cover my favorite way of creating a tongue-and-groove joint in my next blog.

Comments

Nutsaver?

That works, too – but soft-jawed plumbing pliers are already in my tool box, so...

They remind me of plumbing. I hate plumbing. The verb, not the noun.

I bought a pair so soft-jaw pliers because a luthier I follow uses them. I'm not yet a free thinker in the realm, so I do whatever I see him do. I'm shocked at how often I use them, and I think they've yet to touch a guitar.

Thanks for this blog. I now see what my straight rabbet plane really is. It came from my late German father-in-law. I thought it was a wooden version of a shoulder plane. I use it a lot to make rabbets but also like a shoulder plane, since I don't own one. It is not really as good as a chisel for trimming tenons though. I really want to repair a wooden skewed moving fillister I bought at a flea market. (It's badly worm eaten.) It does have a knicker but no depth stop. I would like a depth stop, and I do like the knicker.

Pretty rad post. Really looking forward to the next one!

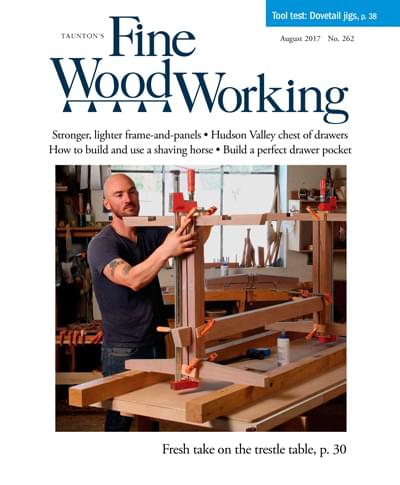

She wrote: "I’ve found that the knob on the front exacerbates this tendency". Looking at the picture of her using the plane, don't see how any of the knobs are removed. Which one is considered the knob on the front?

Log in or create an account to post a comment.

Sign up Log in