Flat and Square by Hand

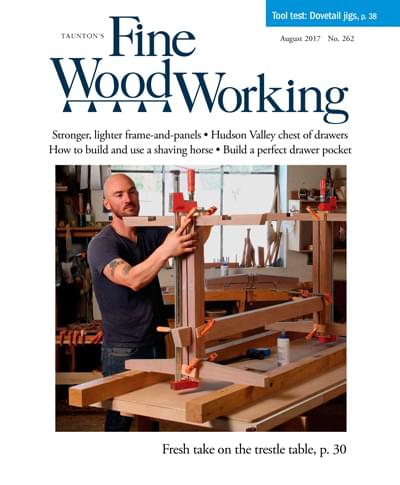

Using hand tools to plane a board flat, straight, and square will train your eye to recognize properly milled stock and build basic skills in layout and handplaning.

Synopsis: The first task assigned to any student in Phil Lowe’s furniture-making classes is to use hand tools to plane a board flat, straight, and square. This is more than just an exercise–this assignment trains the eye to recognize properly milled stock, and it builds basic skills in layout and handplaning.

You often don’t learn the value of stock that is flat, straight, and square until you’ve made furniture from material that isn’t.

You find out soon enough. A cupped drawer side fights back when you try dovetailing it to the front. A twisted apron can set a table’s legs askew.

That’s why the first task my students must complete is to mill by hand a piece of hardwood stock flat, straight, and square. This assignment trains the eye to recognize properly milled stock, and it builds basic skills in layout and handplaning.

Start by tuning your plane iron

Start with a no. 5 jack plane or a no. 4 smoothing plane. If the edge of the plane iron is perfectly straight, the corners of the iron will score the work as you plane. You can avoid this by sharpening the iron with a very slight convex edge. This “crown” is especially useful when planing edges.

I get a convex edge by bringing the iron across a grinding wheel at a slight arc. You also can use a coarse stone and apply greater downward pressure at the corners of the iron. For a smoothing plane, aim for a difference of about 1⁄64 in. between the crown’s peak and the edges of the iron. For a jack plane, aim for 1⁄32 in.

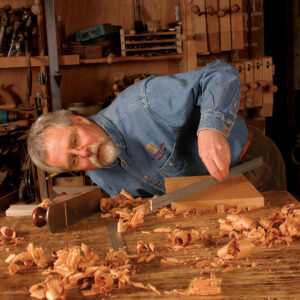

Flatten the first face

Start with a piece of stock roughly 1 in. thick, 8 in. wide, and 10 in. long. Lay a straightedge across one of the broad surfaces from end to end, edge to edge, and diagonally across the corners. Note the high and low spots. Begin taking strokes to bring the high spots in line with the lowest point on the surface. If the board is slightly twisted, with one or two high corners, take diagonal passes from high corner to high corner, working enough of the surface to bring the high areas down to the low spots.

A board that is slightly cupped across its width can be worked with the convex face either up or down. With the convex side down, make straight cuts along both edges to lower the high corners, or make strokes across the board from edge to edge with the plane in a skewed position, working your way down the length to remove the high corners. Use the same technique if the board is tapered, removing thickness at one end. If the board is cupped and the convex side is up, plane straight down the middle until you have flattened the high center.

Check your progress frequently with the straightedge. When the board is nearly flat, finish with a series of straight smoothing cuts along the board’s length and in the same direction as the grain. For the first pass, align the center of the blade—the peak of its crown—with the left- or right-hand edge of the board. The cut will be deepest at the board’s edge. Overlap each stroke by about half the blade’s width. This will put the blade’s crown into the shallowest part of the previous cut, minimizing surface undulations. Check your work again. you’ll know the surface is flat when no light can be seen under the straightedge in any direction. Mark the flattened surface for use as a reference face in laying out subsequent cuts.

First, flatten a face

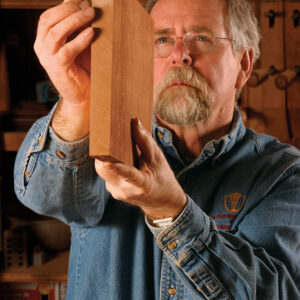

Next, straighten and square an edge

The next step is to plane one long edge straight and flat so that it is square to the reference surface you just flattened. Beginners often want to correct an angled edge by tilting the plane’s body to compensate. This would be required if the iron were ground and honed straight. With a crowned iron, it’s unnecessary. Instead, set the sole in full contact with the edge, aligned so the blade’s crown cuts on the high side of the angle. as you make cuts to remove the angle, shift the plane with each cut until the blade is centered on the edge, bringing the high side down and into square.

To remove a convex surface on an edge, simply make short strokes in the center of the edge and lengthen each consecutive cut until the edge is straight. For an edge that is twisted or high at opposite corners, move the plane laterally from one edge to the other, starting with the plane off to one side as though you were addressing an out-of-square edge. As the cut progresses, the plane will shift so that it is making a cut with the crown in the center, at the square point of the twist, and then gradually will shift to have the opposite side of the crown cutting to remove the opposite angle of the twist.

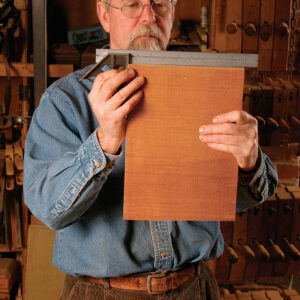

Use a straightedge to check that the edge is straight and flat. use a square, with the head registered against the reference face, to check that the edge is square. Once the edge is straight and square, mark it, too, as a reference edge. you’ll use it to check that the ends are square and that the opposite edge is parallel.

Next, use the edge-planing techniques to plane the ends of the board so that each is square to both reference surface and edge. With the iron adjusted to make a finer cut, use deliberate strokes, working in from both edges and stopping short of the corners to avoid chipping out.

Square an edge

Square the ends

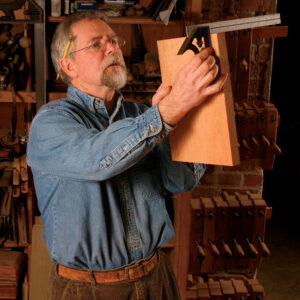

Make the opposite edge and surface parallel

Set the head of the square against the reference edge and use the square’s blade to scribe a reference line indicating the board’s finished width. Plane the opposite edge to this width, checking with the square against the reference face for squareness, and using the head of the square and the blade to check for parallel.

Finally, plane the remaining surface to bring the stock to finished thickness. use a cutting gauge to scribe a line indicating the final thickness. Working off the reference face, scribe the line all the way around the piece of stock. This line will be parallel to the original reference face.

Work to bring the high spots in line with the low point on the surface. as you approach the scribe line, you’ll begin to create a feather edge just above it that falls away as you reach final thickness. This feather edge provides good visual evidence that you are getting the surface flat and parallel. If the feathering develops evenly on all four edges, you’re on the right track.

If you’ve reached the scribe line and still don’t have a parallel surface, strike another line and keep going. Don’t get discouraged. By the time some of my students have completed this exercise, their original 1-in.-thick workpiece is no more than 1⁄2 in. or 5⁄8 in. thick.

Plane the opposite edge

Flatten the opposite face

|

|

|

From Fine Woodworking #191

For the full article, download the PDF below:

Log in or create an account to post a comment.

Sign up Log in