Countertop wine rack

Details like a copper panel, sliding cheese board, and hand-forged hooks make this rack stand out from the pack.

Projects don’t always have to be complicated to be rewarding. Take this elegant little countertop wine rack. It’s chock full of details that enhance the look and function, yet no single step is very difficult to execute. Special features like an illuminated copper insert and a slide-out cheese board make it stand out from the rest.

Start by making the slide-out cheese board. It may seem odd to start with this step, but if you get the glue drying now, it saves time in the long run. Make the cheese board slightly oversize in all dimensions for now, and plane or trim it to final size once the wine rack is built. I chose white oak with walnut accents, but get as creative as you want here.

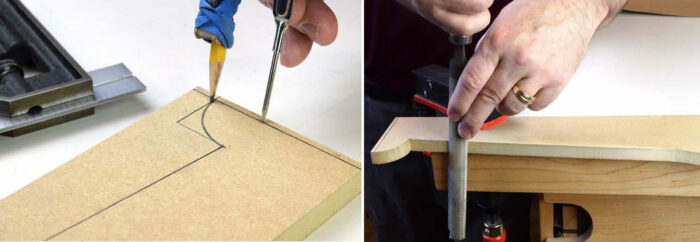

A template helps shape the legs

Make a routing template for the shaped legs from a scrap of MDF. Cut out the template and carefully refine the shape with hand tools. Now use the template to make four identical oak legs. With leg blanks in hand, trace the shape on each one, and rough cut them at the bandsaw. Adhere the template to the leg with double-sided carpet tape to prepare for the next step. Finish shaping the legs with a bearing-guided, flush-trimming bit at the router table. I used a small diameter bit to accurately reproduce the convex shape at the top of each leg, but a larger diameter bit would work too.

Panels and mortises

Glue up the three panels required for the wine rack. You’ll need a top panel and two side panels. Once the sides are dimensioned, set out to mill the six mortises in each. There are perhaps a half dozen possible ways to cut these mortises, but I used a plunge router and straightedge jig. It’s a method that’s a little more stable than a router with an edge guide, and it ensures the mortises will all be correctly aligned. Chuck a 3/8-in.-dia. straight bit into a handheld router, and make a quick straightedge jig for your router. Use glue and brad nails to attach an MDF fence to a strip of 1/4-in. plywood. The dimensions aren’t critical, as long as the jig is longer than your workpiece, and wide enough to contact the bit you intend to use. Now use the router to trim the jig by running it along the fence. You’ve now created a handy reference that clearly shows where your 3/8-in. bit will cut. Position the jig on your side panel layout marks, and plunge the mortises in two successively deeper passes.

Tenons on time and cut correctly

The quickest way to cut tenons must be with a dado blade at the tablesaw. Add an auxiliary fence and miter gauge as you tool-up the tablesaw, and set the fence for a 1/2-in. tenon length (or perhaps a shade less). Blade height for making the cheek cuts is about 3/16 in. Increase blade height to 1/4 in. for the shoulder cuts.

Trace the semicircular shapes on the wine bottle rails, marking two curves on each rail. The curves are 1-1/2 in. diameter for the front rails, and 3 in. diameter for the rear rail. Using a bandsaw, cut just outside your pencil lines to remove most of the waste, and sand the parts smooth. Luckily, most oscillating spindle sanders have sanding sleeves in these diameters, making this a quick and easy job. If you don’t have a spindle sander, consider drilling the holes in oversize parts before cutting the joinery. Then you could simply rip them in half to divide the holes.

Assemble the frame in two steps

Hold the legs next to the side panels and make tick marks for biscuit slots. Biscuits are great when you have several parts coming together with no other interlocking joinery. I find biscuits more forgiving than dowels when it comes time for permanent assembly, although each method has its place in my shop.

Willie’s plans for this build are available here

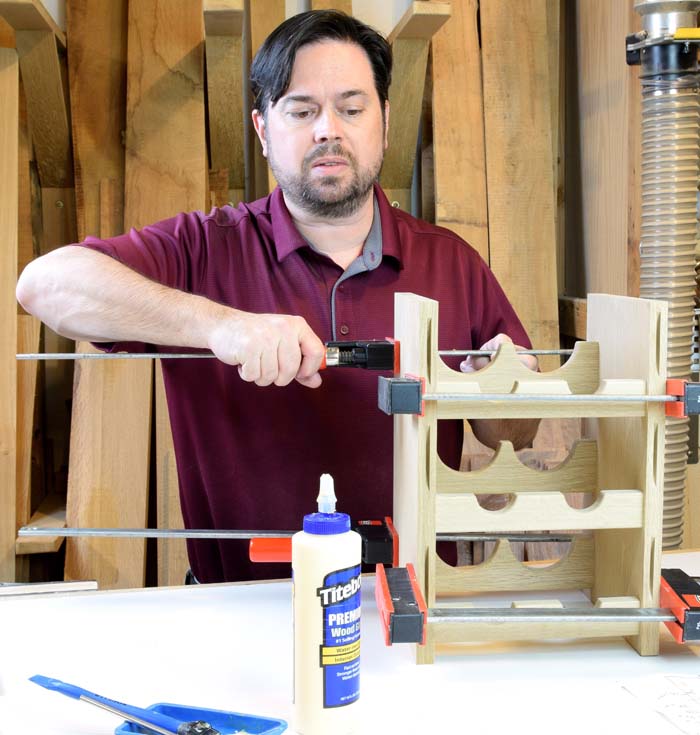

Ease the edges of any parts as needed, and sand them at 120 and 150 grit. Now you’re ready for the first carcase assembly step. Glue the wine bottle rails into the side panels, and clamp the panels together on a flat surface.

Take a moment to cut a rabbet on both back legs. Once assembled, these recesses will receive the copper-faced 1/4-in. plywood back panel. Now move on to the second phase of the assembly and add the legs to the frame. Once the glue cures from the first assembly phase, remove the clamps and glue the legs in place. Here’s where the biscuits really help with alignment. Just align the top of each leg flush with the side panels as you clamp them home.

Back to the cheese board

Now you’ll notice a little pocket of space under the lower wine bottle rails. Let’s make use of that space and finish up the cheese board that was glued up earlier. Plane the cheese board until it easily slides under the rails, and rip it to width. When cutting the cheese board to length, plan for it to be inset from the front legs about 1/8 in.

Copper adds a special touch

To give the wine rack a unique look, add a copper sheet to the plywood back panel. Size a piece of 1/4-in. plywood to the same dimensions as your copper sheet. Copper is commonly sold in a 12 in. by 24 in. size. Cutting copper sheets requires a special technique for safe and accurate results, but luckily you don’t need any special tools. The absolute key to cutting copper sheets is to adhere it to a substrate first. Use spray contact adhesive like 3M 90 high strength to coat both surfaces. Let the contact adhesive tack over for a minute or two, and press the copper sheet onto the plywood back panel. Ideally the pieces would be the same size, or the copper slightly smaller than the plywood. You only want to cut the copper where it’s adequately supported by the plywood backer.

Finishing

With the prep work and finish sanding complete, mix up a batch of Non Grain Raising Dye (NGR). I used Transtint Golden Brown concentrate mixed with one pint denatured alcohol and one pint lacquer thinner. Although Transtint dyes are soluble in almost any liquid (except mineral spirits) this 50/50 mix of alcohol and lacquer thinner is what makes it an NGR dye. Combine the 1-qt. mixture of solvents with a 2-oz. container of dye concentrate. Apply the dye with a terrycloth wrapped sponge (staining sponge). Wet the sponge with dye, but don’t make it dripping wet. Move quickly when applying the dye, and only go over each area once. Having a helper is a great idea so you can cover all surfaces in short order, then walk away. Once the dye dries, apply a coat of Bullseye Shellac Sealcoat, which is a thin de-waxed shellac. I like to spray finishes, but shellac can be wiped or brushed on if you must. Scuff-sand the shellac with a fine sanding sponge, and clean the surface with cheese cloth and compressed air. Now glaze the project with General Finishes Antique Walnut gel stain. Wipe on the gel stain with a lint-free rag. Let the stain dry overnight (THE most important step!) and move on to the final step: a topcoat of your choice. I sprayed a pre-catalyzed lacquer in a satin sheen, but amber shellac would be another option.

Final details

Only a few steps remain to finish the wine rack. Drill recesses for figure-8 fasteners to attach the top to the frame. I used one fastener near each corner, and installed them with #6 x 5/8-in.-long screws. One optional accessory is a light bar to highlight the copper back panel. If you decide on a light, make a template the same size as your light. Clamp the template in place and rout a 1/2-in.-deep recess with a bearing-guided bit. Now add the wine glass holders to the overhang area. These are made from a single length of wood with a bevel ripped down one edge. Cut the pieces to length and install them with brad nails. Finally, add the decorative hooks to the front of the wine rack. The hooks pictured are hand-forged iron with copper nails, and were made by a Pacific Northwest craftsman. They are available from SolForge on Etsy.com. The copper nails that come with the hooks are a little too long, but are easily trimmed with wire cutters.

Willie’s plans for this build are available here

Comments

All that, and not one picture of the copper?

“[Deleted]”

Here are a couple pictures of the copper panel for you.

And this one.

But where does it belong on the wine rack?

It's kind of hard to see but it looks like it goes in at the back of the rack. You can see a bit of it in the picture of the wine rack at the top of the page. If I had to guess I'd say it fits into grooves and is captured by the top and something at the bottom.

There are rabbets cut in the back legs. It just installs from the back with screws.

The key to cutting copper is to attach it to the 1/4" plywood first. I used 3M 90 spray, but liquid contact cement would work fine as well.

Thanks

Can you share any drawing or dimensions?

Are there dimensions available, or plans that can be downloaded?

I’ve hit the link for the plans and my DropBox opened and showed a page of Chinese characters and emojis.

It’s got SketchUp file extension of .skb and I’ve changed it to .skp to see if I could open it.

Any other suggestions?

You're right. I'm looking into it with Willie.

Try it now.

I wish there were plans for this item that I can use. I have not been able to successfully navigate any of the link provided in FWW.

You need to have Sketchup installed on your computer to view the plans. Sketchup or Sketchup Make is a free program. If you tried to access plans on your phone, just try again on a desktop with Sketchup.

Best of luck!

Log in or create an account to post a comment.

Sign up Log in