STL222: The call of the solid-wood chessboard

Mike, Anissa, and Ben discuss more tablesaw safety, solid-wood chessboards, hotel woodworking for a heath care worker on covid assignment, and sawing a wooden blimp in half. Plus, a new jingle and a new boss!

Question 1:

From Bill:

Assuming the table saw has a riving knife (or even a splitter) in place, would there still be the possibility for kickback in the described ripping operation? My understanding is that the riving knife virtually eliminates the occurrence of kickback. Is this a correct understanding of the riving knife’s kickback mitigation? If so, what advantage then does the bandsaw have over the table saw, if any, in the example of ripping this board in half?

In my home shop, my preference has been to do ripping operations on the table saw equipped with a riving knife because (1) I’m under the impression it’s safe, (2) the larger table saw surface makes the operation feel more stable, and (3) my bandsaw doesn’t have a very good fence. So am I safe ripping on the table saw when using a riving knife or splitter, or am I unwittingly hanging it out there?

—

From Jim:

I appreciated your recent conversation about table saw safety. While you were talking, I wondered about two situations, both of which I think I’ve seen in FWW videos. Can you comment about the risk level of putting your hand on top of a board for downward pressure when running it over a dado stack or on the jointer. I always try to avoid doing this, but I wonder whether I’m being overly cautious.

|

|

|

Question 2:

From Matt:

How would you go about safely sawing a blimp shaped object in half down the long side? The objects are too thick to cut on the table saw and after being cut in half will be put back together so I didn’t want to risk flipping it on the table saw and misaligning the cut. I ended up building a sled with two 45 degree angles butted up against each other so the object would self center but this meant the object would be going through the bandsaw blade with no support on either end. I then used 16 gauge brad nails to attach cauls to the top and clamped them down giving essentially four points of pressure and locking the piece in place. I then used a featherboard to keep the sled tight against the fence. When the blade neared the clamp, I shut the saw off and moved the clamp to the other side to finish the cut. It worked great, but I didn’t really enjoy hiding behind my mitre saw station and using a long push stick in case the object became a football sized missile.

Segment Potpurri

Anissa – Christian Beckvoort using a switchable magnet as a drill press fence

Ben – Just screwing up every aspect of wood movement on his dining room table

Mike – Bob Van Dyke’s technique of gluing the hinges in place in order to perfectly align a box top

Question 3:

From William:

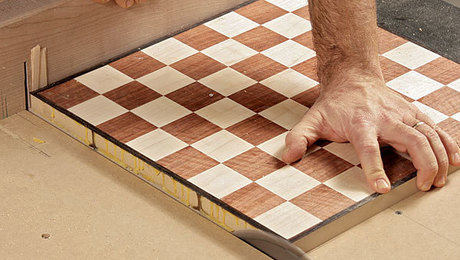

I want to build a chess board with a frame and panel design. For the board itself, I just want to make it out of 3/4 thick strips. I will be gluing end grain to end grain in order to create the alternating pattern of dark and light. I have done a mock-up out of fir that seems strong enough and I have seen tests of end grain to end grain bonds that perform well enough. However, I am worried about long term strength. Is that being paranoid? Do any of you have any long term successful end to end grain joints?

|

Question 4:

From Dave:

I am a clinician who took an assignment to be part of the COVID response here in the US. As a result, I’ve been living out of a hotel room since April 9th and I will probably continue to do so for a long time. What kind of craft do you think I could make work in my situation? I’m going a little nuts – I love the work but I starved for play in my downtime. Factors I’m considering are:

- I can have family go to my place and ship a few tools, but I’m also willing to use this as an excuse to buy a few new tools

- I’ll have some room in my checked luggage, but not a lot

- It’s all health care workers in this hotel, we all work different shifts, so I don’t want to be too loud and disturb their sleep

- I’m working nights, 7d/wk, indefinitely. So even if I could access shop space, I don’t know when I would because I’ve become a creature of the night.

What comes to mind is lettering and/or chip carving. Something I’ve never done before. I figure a lot may not be worth keeping, or I can give them to folk here and not worry about how to get workpieces back home.

Recommendations:

Ben – Buy more flashlights

Anissa – Check out the Brady Bunch and The Wonder Years again. They hold up well.

Mike – Consistently visit your local farmers market

Every two weeks, a team of Fine Woodworking staffers answers questions from readers on Shop Talk Live, Fine Woodworking‘s biweekly podcast. Send your woodworking questions to [email protected] for consideration in the regular broadcast! Our continued existence relies upon listener support. So if you enjoy the show, be sure to leave us a five-star rating and maybe even a nice comment on our iTunes page.

Comments

Wow... I am a cyclist and woodworker, both for over 35 years... Cannot imagine living with the paranoia of "everyone in a car is out to kill me" and "every time I rip on the tables I assume it will kick back"... I have had kickback on a tables when ripping before I bought a tables with a riving knife, but none since. I routinely rip long boards (often 4-5', periodically 6'+) on the tablesaw without difficulty or danger - Using a bandsaw for such rips with it's small table just seems unwieldy to me...!

I was totally shocked by your advice to not rip boards down the center on the tablesaw. I've been woodworking for 3-4 years, read many books and articles, watched many videos, and I feel like nobody talks about this.

I typically work with S2S or S4S stock (since I don't have a jointer) and often will rip several parts out of a wider board. Generally, this has felt safe, but I have had a few times (mostly when working on a project with khaya - which has interlocking grain) when the board would pitch the riving knife and even stop the blade on my 1.75 hp saw. This made me stop and wonder, but I'd never heard this as general safety advice, so I didn't make any change to my technique.

I only have a small bandsaw and no jointer, so I'll have to think about how I deal with wider boards. Maybe use a straight-line ripping sled to rough dimension? When you suggest "final dimensioning only" on the tablesaw, about how much stock should I be removing on the outside of the blade when ripping???

Yup - if you don't have a jointer you can use a long sled or if you have a track saw create a straight edge first before ripping on the tables.

+1 on the track saw. It's a game changer for cutting plywood too. Kreg makes a pretty decent one on the low end of the price range.

Ben, I think your dining table problem is a gift in disguise... Turn it into a split-top Roubo dining table and create a space to organize silverware, condiments; maybe even a wine rack?

Just make sure the center tray is removable - you do not want crumbs accumulating in there.

I eagerly await the article.

The audio-only stream seems to be episode 192 instead.

Could it please be replaced with the correct one?

One of the Krenov books has a description of construction of a solid wood chess table. If I remember right, he left tiny spaces between the blocks for the squares, which were then connected by dowels. Must have been very hard to keep the squares aligned, but Krenov could do it.

Log in or create an account to post a comment.

Sign up Log in